There are high manual screening

costs and low efficiency.

Sorting cotton based on lightness is impossible for common color sorters.

Common color sorters have inaccurate identification of foreign fibers in cotton when relying solely on color.

Importing prism spectrographs from

the current market incurs high costs.

The traditional algorithm has a detection speed of 10-15 m/s, resulting in low efficiency.

The detection rate is low, ranging from 70% to 80%.

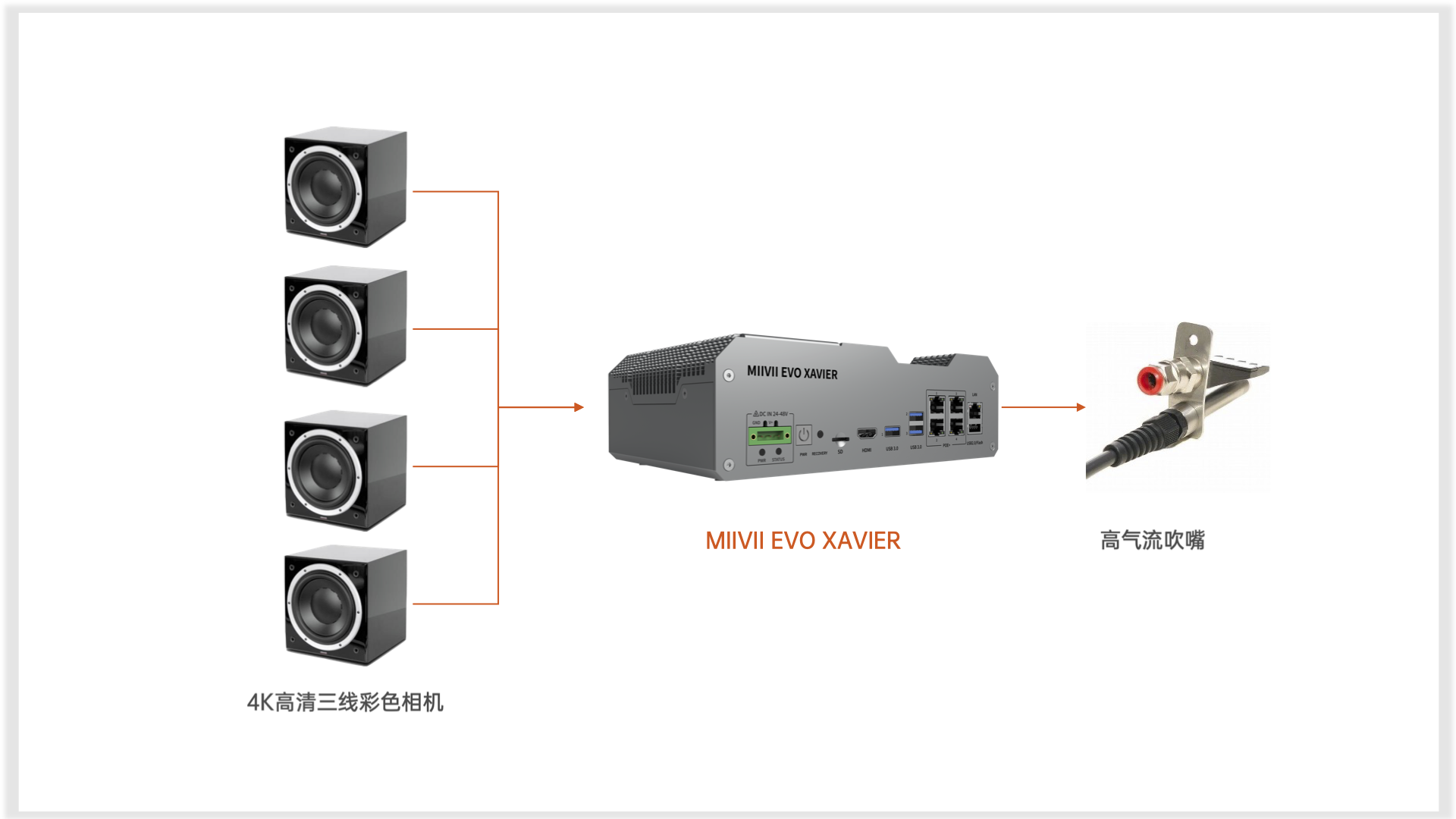

Detection and computation of foreign fibers in cotton using the MIIVII EVO Xavier.

Relying on the powerful encoding and decoding capabilities of the NVIDIA GPU,

the EVO Xavier can analyze image data collected by the camera in real time, identify

foreign fibers and control high-flow nozzles to sort cotton based on detected lightness.